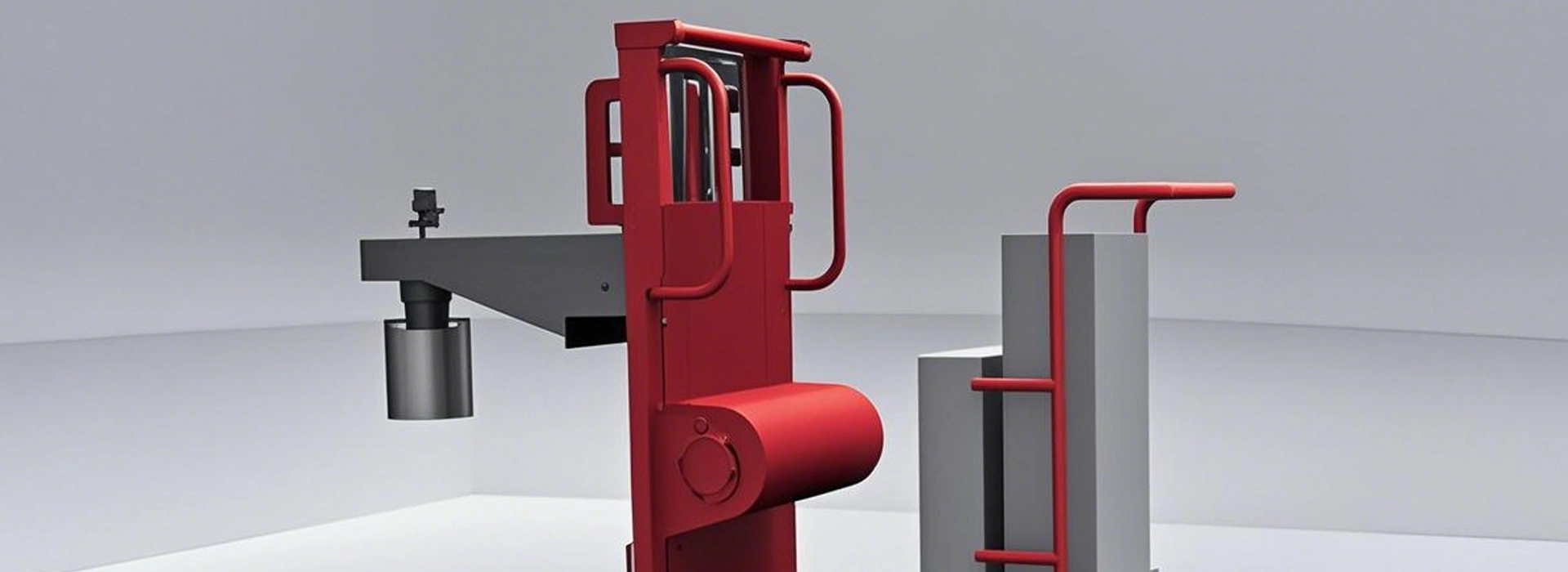

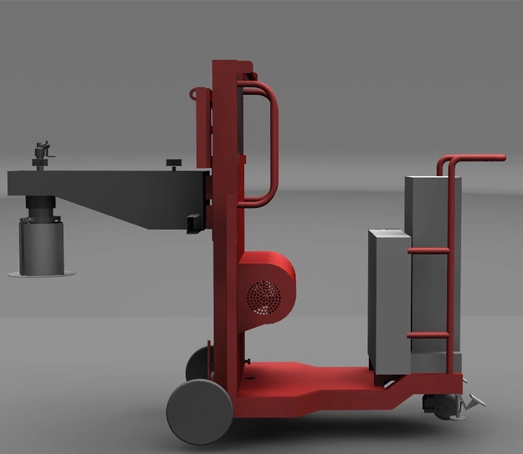

Hydrogen is a common and troublesome impurity in molten aluminum. An advanced aluminum degasser effectively extracts hydrogen from the melt. By introducing an inert gas, like argon, which forms tiny bubbles, hydrogen diffuses into these bubbles and is carried out of the molten metal. This reduces porosity in the final aluminum products, making them stronger and more reliable.

An aluminum degasser is a vital tool in aluminum processing. It removes hydrogen and other impurities from molten aluminum. By bubbling an inert gas through the melt, it improves the quality of the aluminum, reducing porosity in castings and enhancing mechanical properties.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский