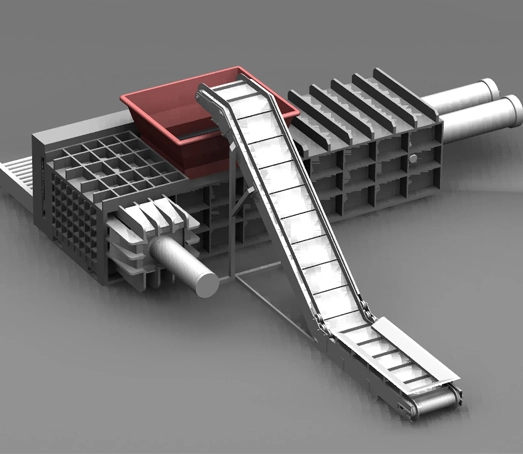

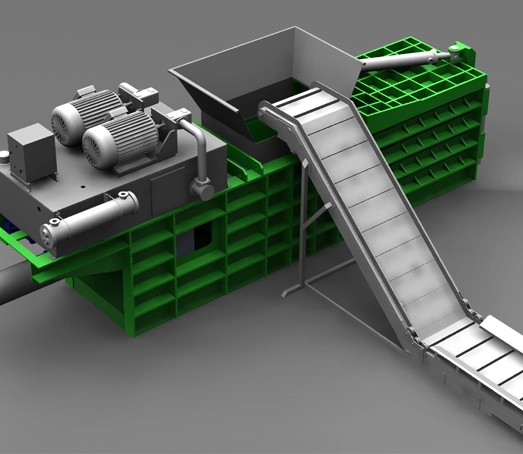

Facilitate Transportation: Metal materials are usually heavy, such as waste steel and iron products. Strong compression force can tightly pack them into small - volume and high - density bales, which is convenient for loading, unloading and transportation. This reduces transportation costs and also decreases the space occupied during transportation.

Enhance Recycling Efficiency: In the recycling process, the compressed metal bales are more regular, which is beneficial for subsequent smelting, processing and other procedures. It can improve the recycling efficiency and increase the metal recovery rate.

Reduce Oxidation: Strong compression force can minimize the gaps between metal materials, reducing the contact area with air. Thus, it can lower the degree of metal oxidation during storage and transportation, improving the quality of the metal.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский