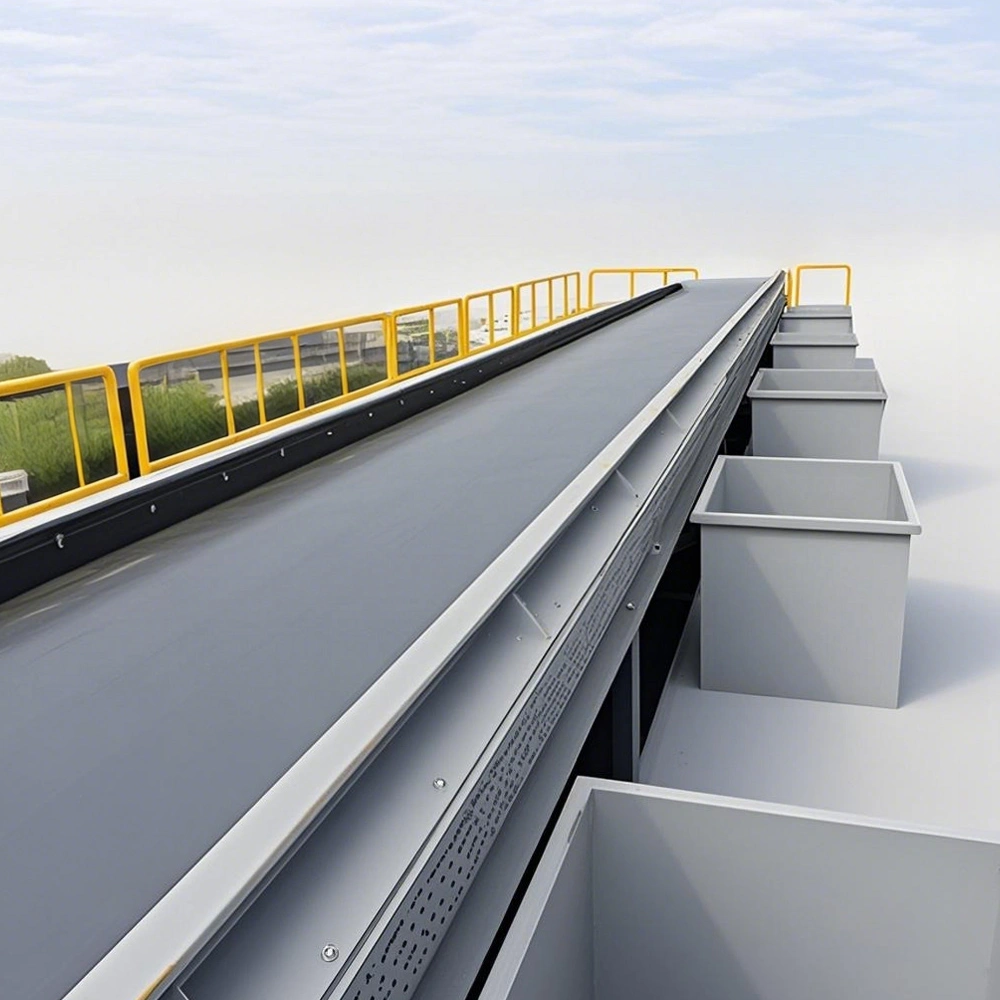

Advantages of Manual Sorting Platform

1. Significant cost effectiveness

Manual sorting platforms do not require high initial investment, equipment and deployment costs are much lower than automated systems, and are especially suitable for small and medium-sized enterprises or scenarios with limited budgets

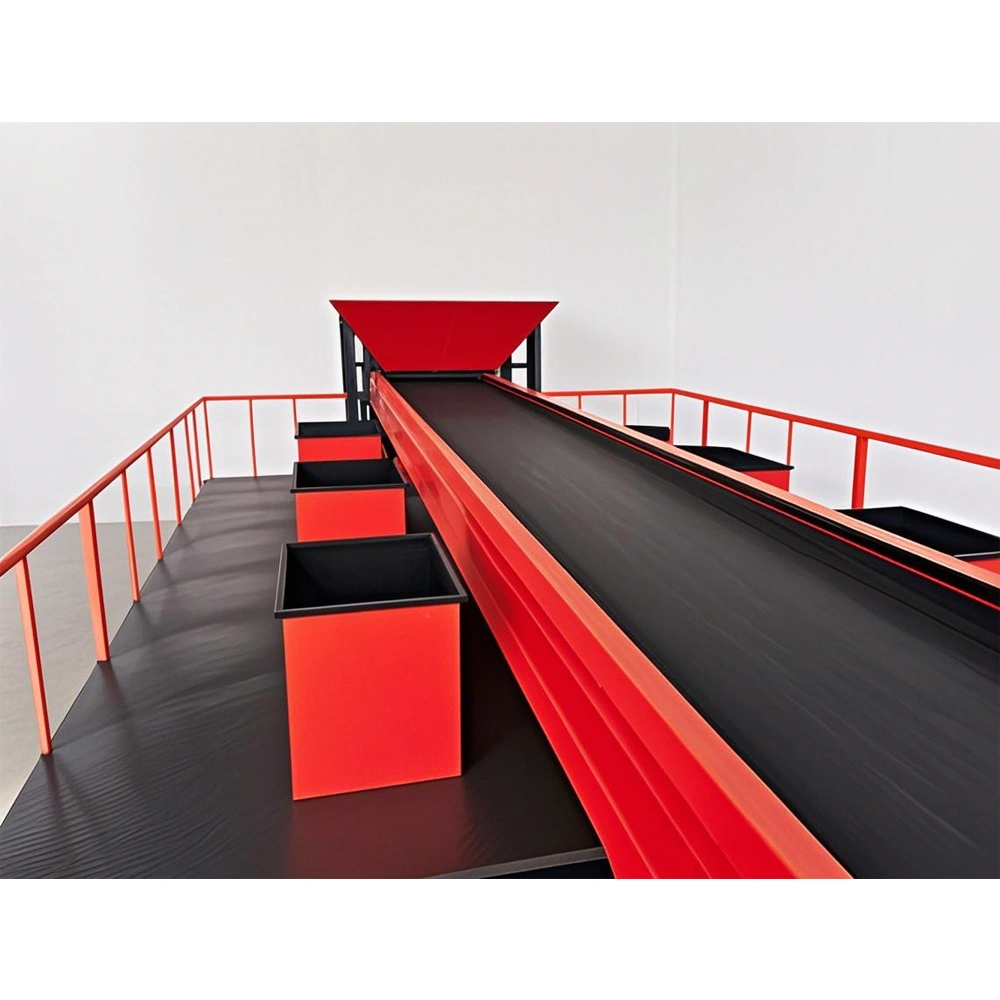

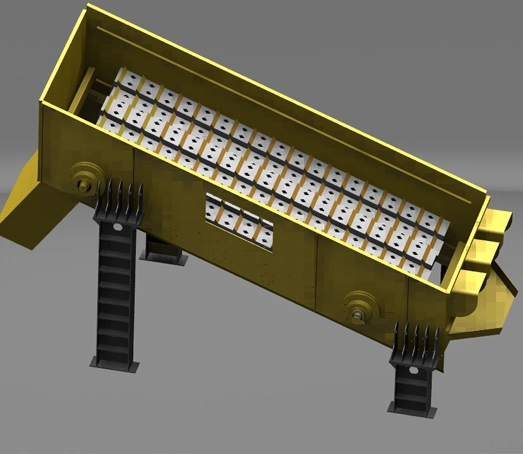

2. Flexibility to adapt to diverse needs

The modular design allows for rapid adjustment of the sorting process in response to changes in product type, size or sorting rules.

3. Handle complex scenes accurately

Sorting modes that rely on human judgment perform well in fine classification, especially in situations where subjective decisions are required, such as distinguishing items of similar appearance, recognizing special marks, or handling sensitive documents.

4. Man-machine collaboration optimization efficiency

The platform supports hybrid integration with automation tools, a model that reduces repetitive labor and avoids the rigid defects of fully automated systems, improving overall performance while maintaining flexibility.

5. Sustainability and scalability

Manual sorting allows you to flexibly increase and decrease manpower to cope with business peaks without the need to upgrade equipment for short-term needs. In addition, the platform design focuses on durability and can adapt to harsh environments (such as wet, dusty places), extending equipment life and reducing long-term maintenance costs.

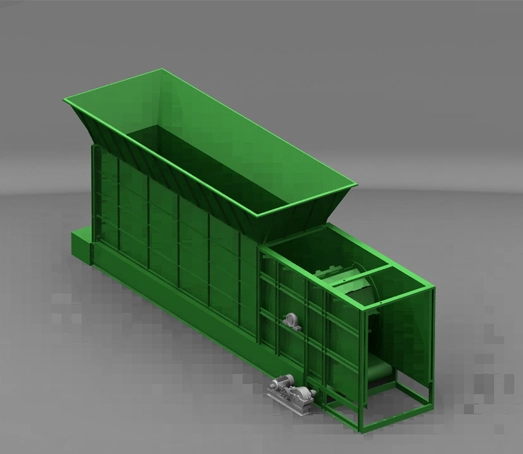

Applications of Manual Sorting Platform

1. Logistics and e-commerce sorting

Handle special-shaped packages, fragile goods or specially marked goods, combined with a code scanning system to improve sorting accuracy.

To cope with the peak of e-commerce promotion, through the dynamic deployment of manpower and equipment to achieve flexible capacity.

2. Food and agricultural processing

Artificial screening of fruit and vegetable defects, grading, to ensure quality consistency; Sort seafood, meat and other perishables.

Suitable for small batch multi-variety production, such as nuts, tea fine classification.

3. Recycling and resource management

Mixed waste sorting (plastic, metal, paper), combined with an AI vision system to identify material types.

In hazardous waste treatment, manual intervention reduces the risk of misjudgment and ensures safety.

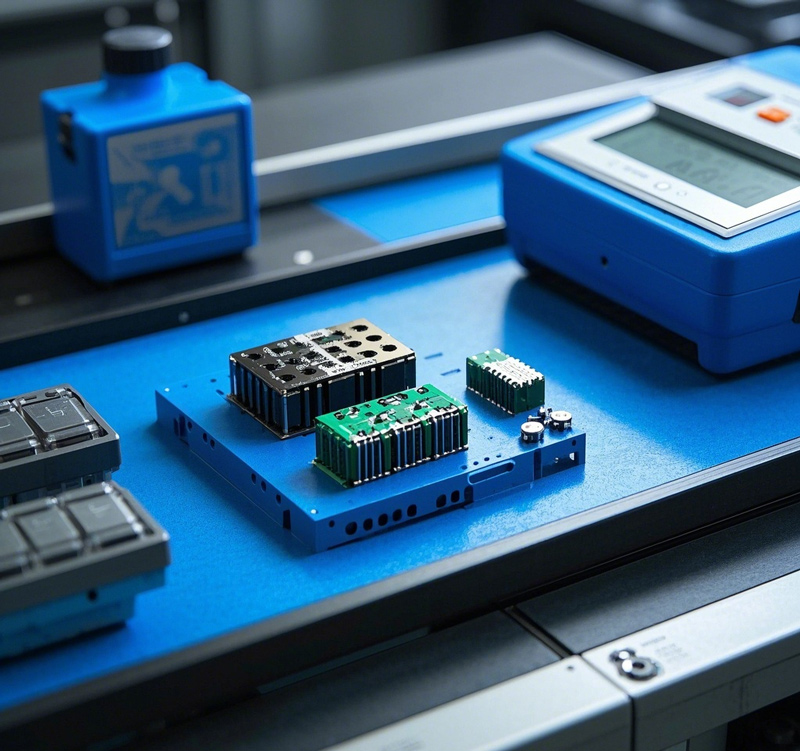

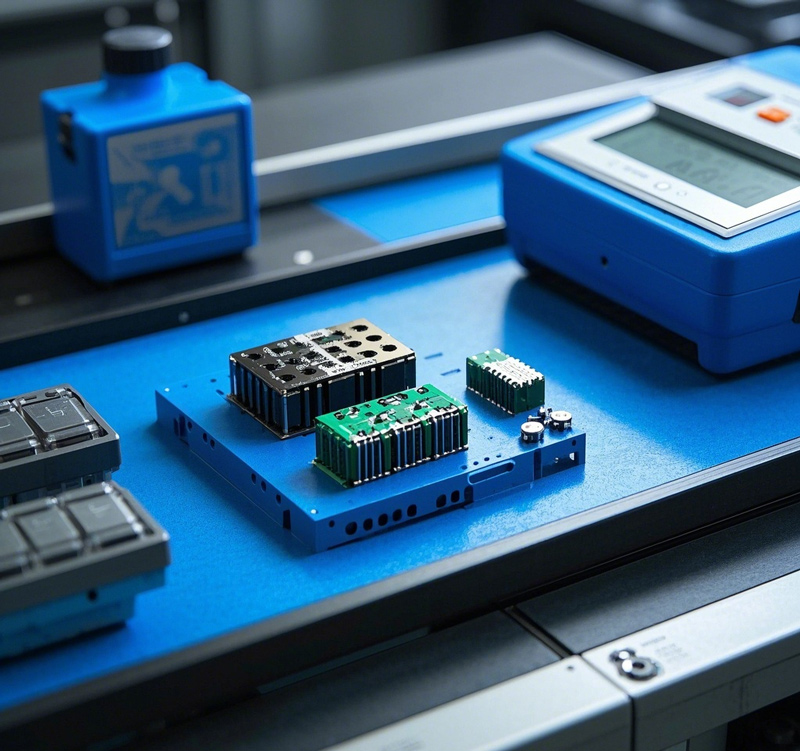

4. Manufacturing and parts sorting

Manual inspection and classification of electronic components and precision parts to ensure no damage operation.

Auto parts sorting, adapt to the needs of complex models, reduce the rigid limitations of automation systems.

5. Document and file management

Sensitive documents are manually classified and archived to ensure information security; Pre-processing of historical archives before digitization.

Library book sorting, according to the category, borrowing status dynamic adjustment process.

6. Medical and Pharmaceutical

Manual inspection of drug packaging to ensure batch correctness; Sorting and labeling of laboratory samples.

Adapt to the multi-specification requirements of medical consumables, such as the fine classification of surgical instruments.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский