When is an Aluminum Chip Dryer Necessary?

1. Excessive Moisture or Coolant in Chips

Wet aluminum chips increase oxidation, energy consumption, and safety risks during melting. A dryer removes residual coolant and oil, ensuring higher recovery and cleaner aluminum feedstock.

2. Low Metal Recovery and Safety Risks

If you experience melting losses, slag build-up, or steam explosions, wet chips are likely the cause. Drying them beforehand greatly improves metal recovery and furnace safety.

3. Environmental and Compliance Demands

Moisture and oil in chips generate VOC emissions and smoke. A chip dryer with an exhaust treatment system helps meet environmental and safety regulations.

4. High-Volume or Continuous Operations

For large-scale or automated machining, manual chip drying cannot keep pace. A continuous aluminum chip dryer keeps production stable and efficient.

5. Higher Profitability and Quality Goals

When drying improves recovery rate, reduces energy costs, and enhances product quality, an aluminum chip dryer turns from an optional tool into a key investment.

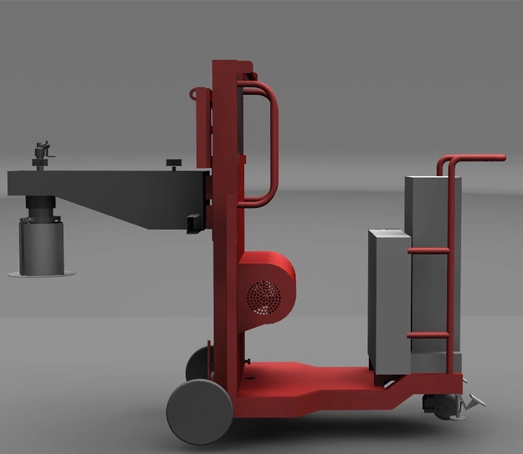

How aluminum chip dryers Work

Aluminum chip dryers operate by using controlled heating and airflow to remove moisture, cutting fluids, and oils from aluminum chips generated during machining processes. First, the wet aluminum chips are fed into a rotating drum or continuous drying chamber. As the chamber rotates or vibrates, the chips are evenly agitated, ensuring uniform exposure to heated air.

A high-efficiency burner or electric heating system raises the internal temperature, while a forced-air circulation system accelerates moisture evaporation. During this process, vapors and residual oil fumes are extracted through an exhaust or filtration system to maintain clean operation and prevent contamination. By the time the chips reach the discharge end, they are thoroughly dried, clean, and ready for briquetting, recycling, or remelting.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский