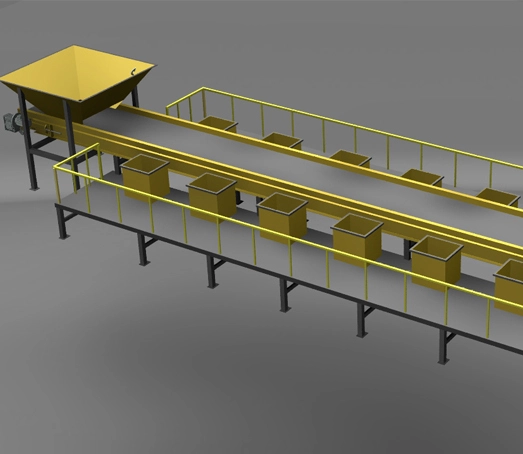

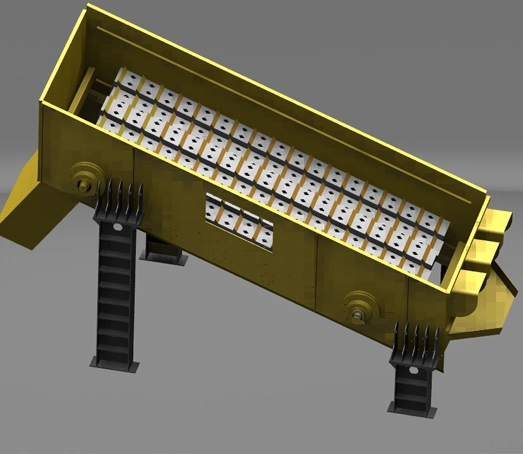

Auto feeder is a multi-functional industrial equipment, through high frequency vibration to achieve material compaction, settlement, degassing and packaging optimization, widely used in concrete pouring, casting, food processing, packaging and material testing and other fields. The equipment adopts dual motor synchronous drive technology to provide linear vibration mode to ensure uniform and dense materials, reduce the air gap in the container, reduce the container usage by up to 20%, and reduce the material loss during transportation. Its modular design supports customization, ADAPTS to different load requirements, the vibration frequency range covers 20-150Hz, and the amplitude and exciting force are adjustable. Equipped with intelligent control system, support automatic filling, weighing and anti-overload protection, significantly improve production efficiency and product consistency.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский