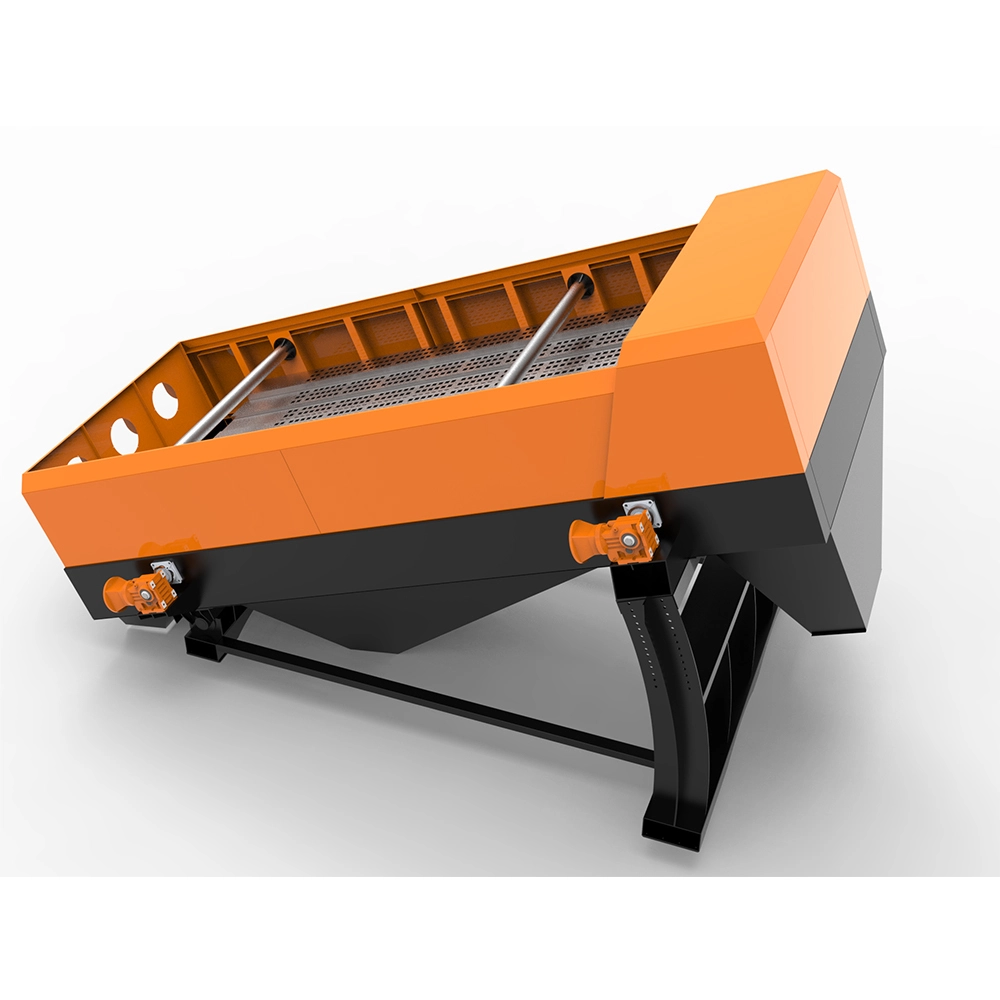

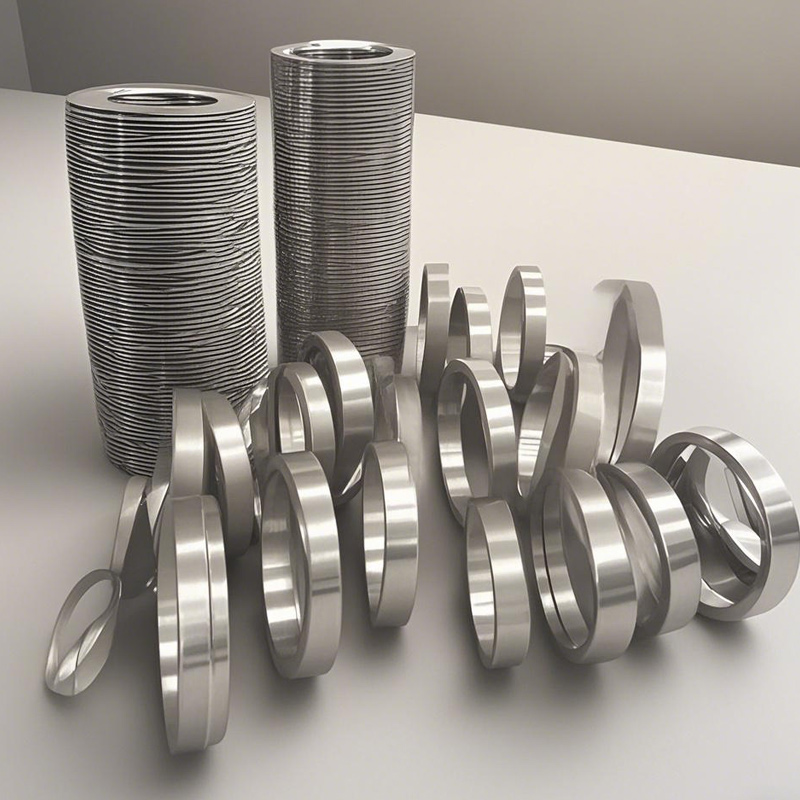

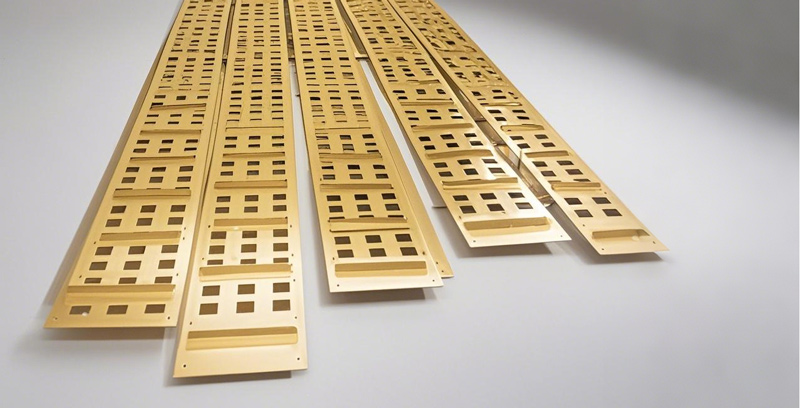

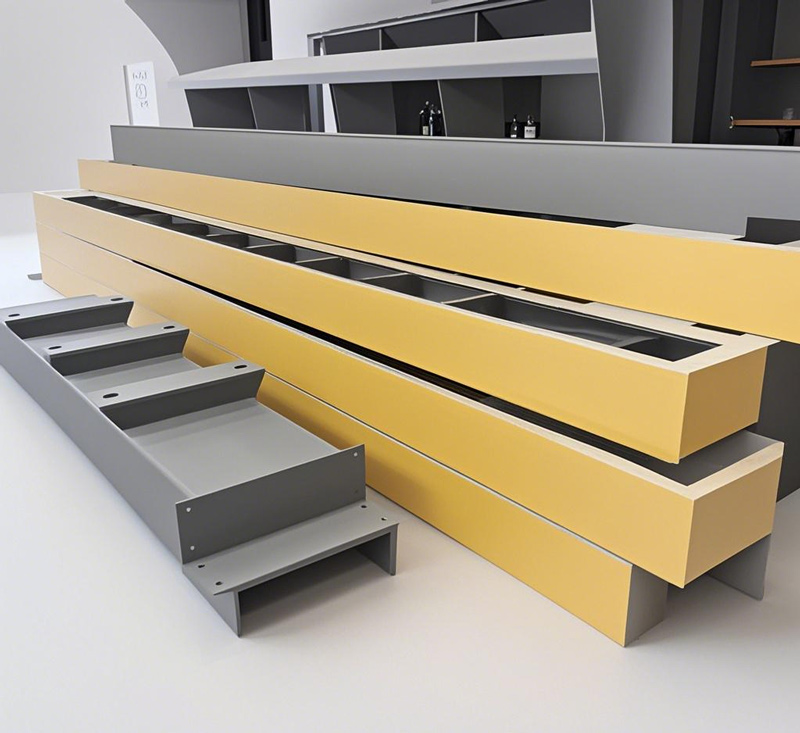

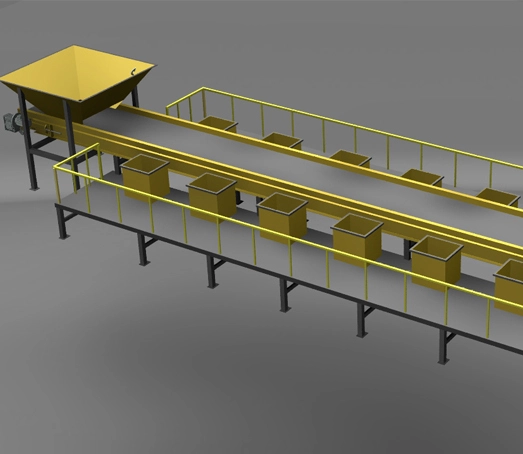

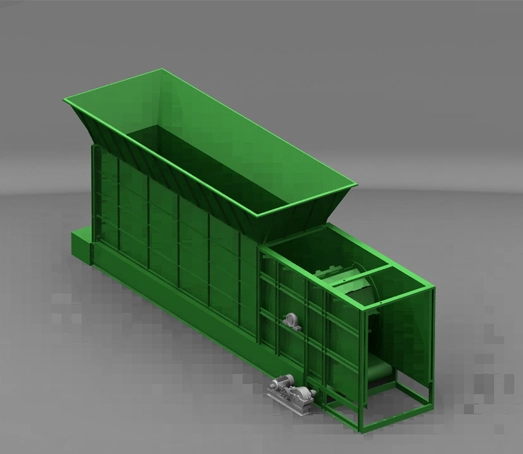

Ballistic separator machines are advanced sorting machines designed to efficiently classify waste materials based on physical properties like shape, size, and density. These systems utilize oscillating paddles or inclined screens to dynamically separate materials into distinct fractions: rolling (3D objects like bottles/cans), flat (2D items such as paper/films), and fines (small particles). Key features include adjustable parameters (speed, inclination) for customization, high throughput (up to 60 m³/h), and energy-efficient operation. Benefits include reduced manual sorting, enhanced recycling purity, and compatibility with wet or dry materials. Widely used in municipal waste, plastics, construction debris, and composting, these machines optimize recovery rates while minimizing environmental impact through closed-loop designs and durable construction.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский