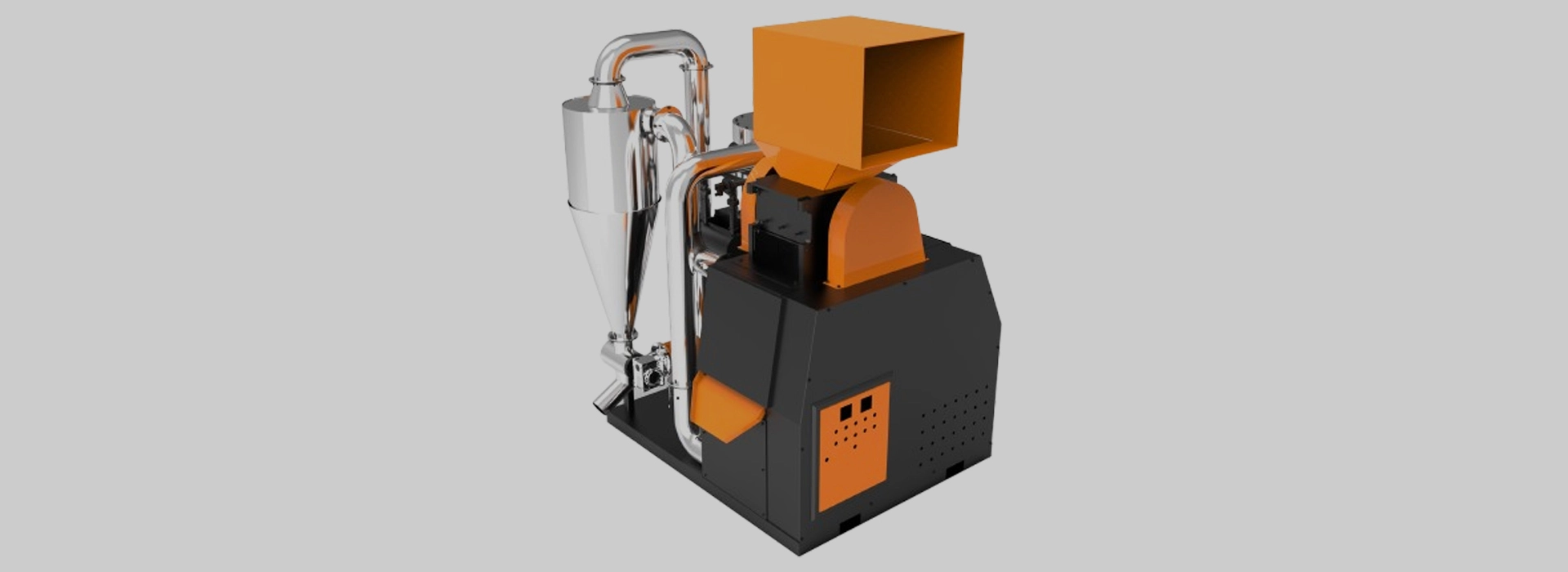

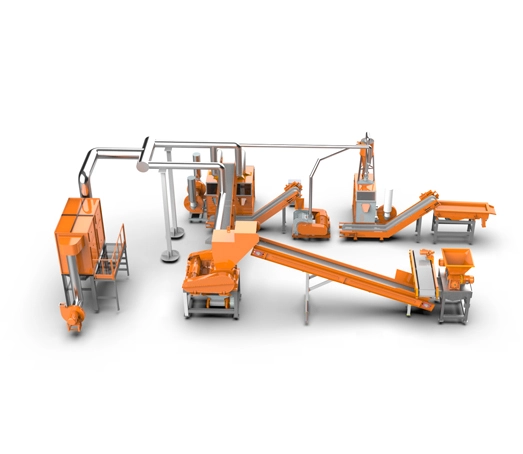

Copper wire recycling machines revolutionize metal recovery in multiple ways.

Firstly, they efficiently separate copper from its insulating materials. Through mechanical or thermal processes, these machines strip away plastic or rubber coatings, ensuring high - purity copper retrieval. This purity is crucial as it fetches better prices in the market.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский