Advantages of Eddy Current Separator

Efficient separation of non-ferrous metals

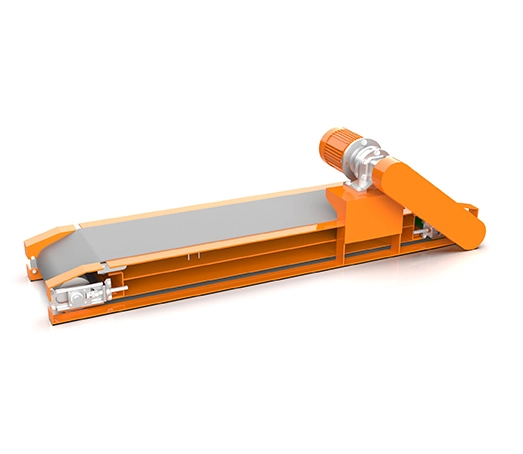

Accurate identification: Through the alternating magnetic field in the metal induced eddy current, generate repulsive force, metal and non-metal (such as plastic, glass, ceramics, etc.) fast separation.

High recovery rate: Especially suitable for handling fine materials, can effectively recover small metal particles, improve resource utilization.

Non-contact operation

No mechanical wear: no direct contact with materials, reduce equipment losses, extend service life.

Protect material integrity: Avoid material deformation or damage that may be caused by traditional mechanical sorting.

Environmental protection and energy saving

No chemical pollution: pure physical sorting, no need to add chemical agents, in line with environmental requirements.

Low energy consumption: Lower energy consumption and low operating costs compared to other separation technologies (such as magnetic separation and flotation).

Automation and intelligence

Intelligent control: parameters can be adjusted (such as magnetic field strength, belt speed) to adapt to different material characteristics to achieve automated production.

Real-time monitoring: Integrated sensors and control systems for remote operation and fault diagnosis.

Wide applicability

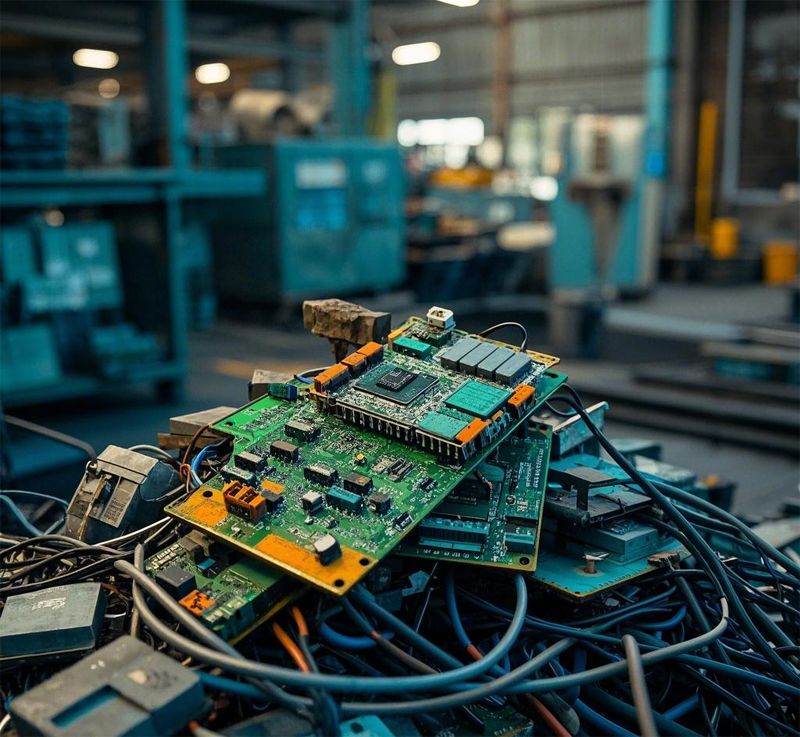

Multi-scenario application: It is suitable for complex materials such as electronic waste, scrap car disassembly, construction waste, and incineration ash of domestic waste.

Flexible configuration: The eddy current sorting machine can be linked with crusher, vibrating screen, belt conveyor and other equipment to form a complete sorting production line.

Support circular economy

Promoting resource regeneration: Efficient recycling of non-ferrous metals contributes to the development of "waste-free cities" and sustainable development goals.

Reduce raw material dependence: Reduce the extraction of primary mineral resources by recycling metals.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский