Advantages of Engine Crusher

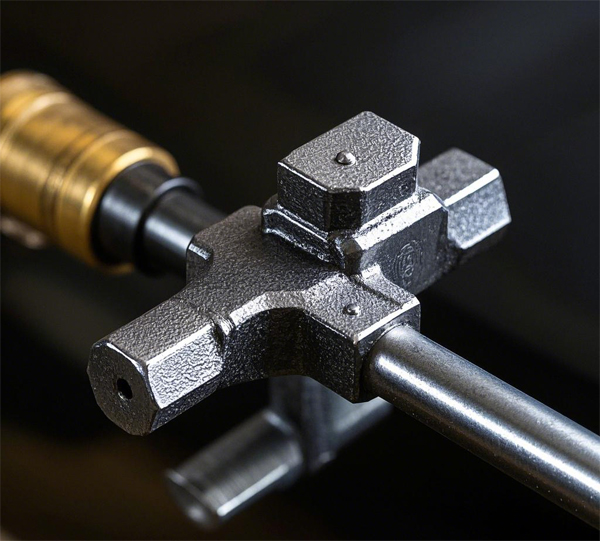

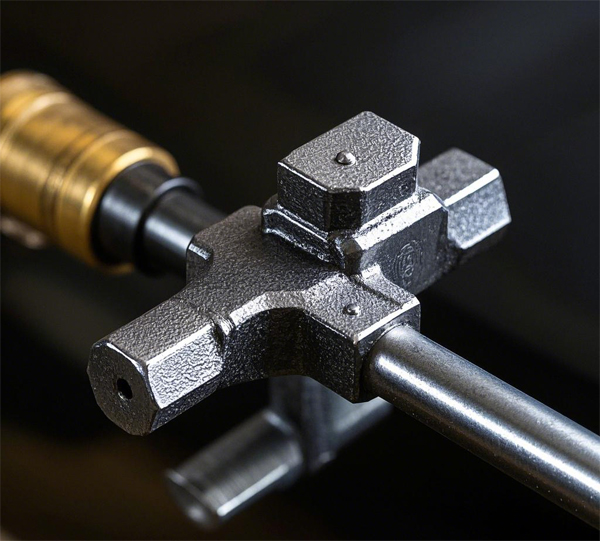

Constructed from high-strength alloy steel with 980MPa tensile strength, the tool withstands extreme torque and impacts. Precision gear alloy steel, surface hardness of HRC58-62, wear life increased by 300%. Hydraulic components are specially treated to enhance corrosion resistance and adapt to harsh maintenance environments.

Applications of Engine Crusher

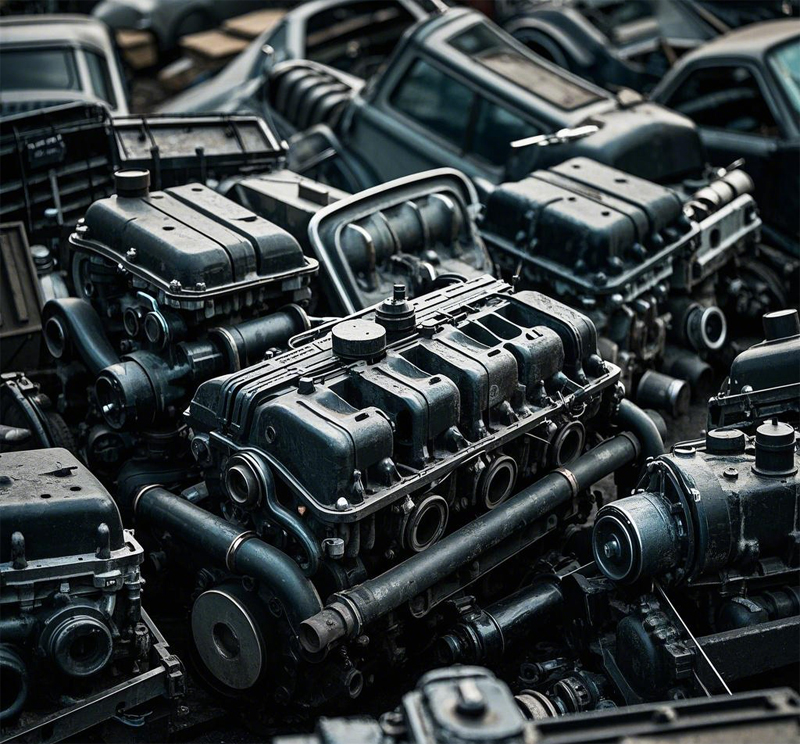

Engine crackers have the following applications in the crushing and recycling of automotive engine blocks and aluminum wheels:

Automotive Engine Blocks

Disassembly for Recycling: Engine crackers are used to carefully disassemble automotive engine blocks. This allows for the separation of different components made of various materials, such as cast iron, aluminum, and steel. The individual parts can then be sorted and recycled according to their material types. For example, the aluminum parts can be melted down and reused in the production of new aluminum components, while the cast iron and steel parts can also be recycled through appropriate processes.

Removing Stubborn Components: Some components in the engine block, such as the crankshaft and camshaft, are often tightly fitted. Engine crackers provide the necessary force and leverage to remove these components without causing excessive damage to the engine block or the components themselves. This ensures that the recyclable materials are in a suitable condition for further processing.

Aluminum Wheels

Size Reduction for Recycling: Aluminum wheels are often large and bulky, which can be inconvenient for transportation and recycling. Engine crackers can be used to crush or break the aluminum wheels into smaller pieces. This not only makes it easier to handle and transport the wheels but also increases the surface area of the aluminum, which is beneficial for the recycling process. The smaller pieces can be more easily melted down and refined to produce new aluminum products.

Separation from Other Materials: Aluminum wheels may have other components attached to them, such as tires and steel rims. Engine crackers can help in separating the aluminum from these other materials. By applying the right amount of force, the connection between the aluminum wheel and the other components can be broken, allowing for the efficient separation and recycling of each material. This helps to improve the purity of the recycled aluminum and reduces the cost and environmental impact of the recycling process.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский