Ensure a continuous and consistent feed of copper - bearing materials. Avoid overloading or under - feeding the machine. A well - regulated supply keeps the machine running smoothly and maximizes processing speed.

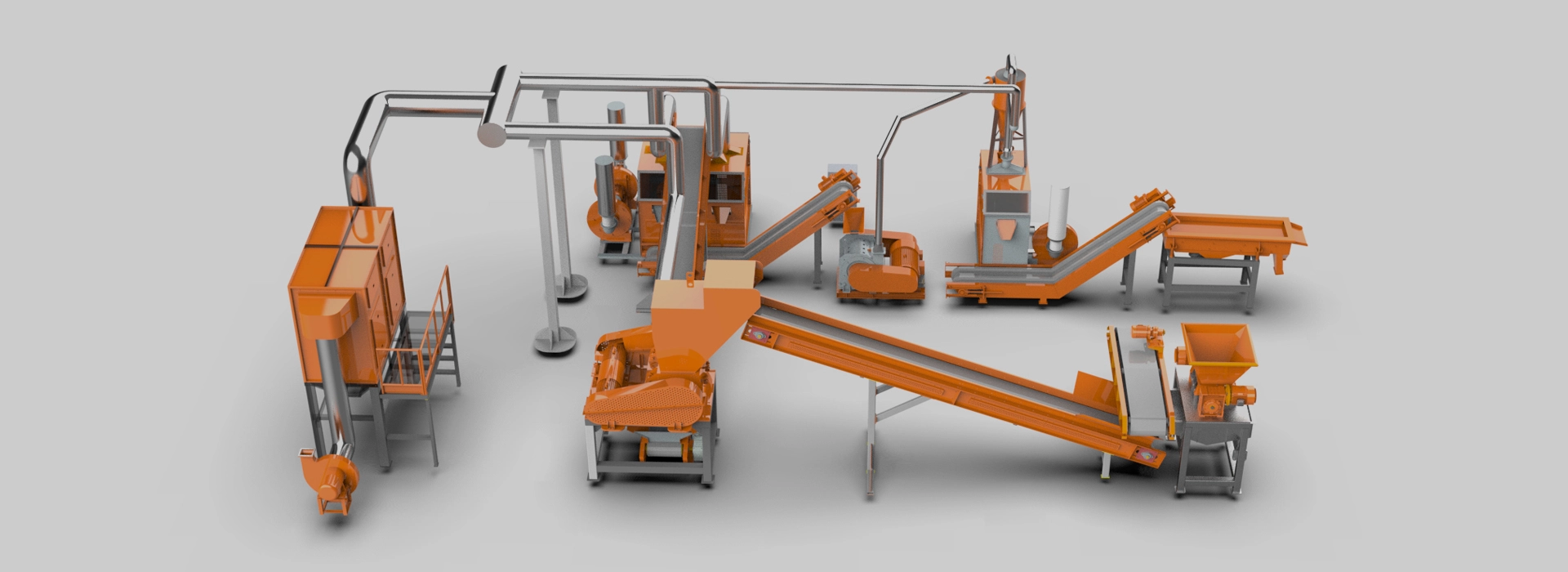

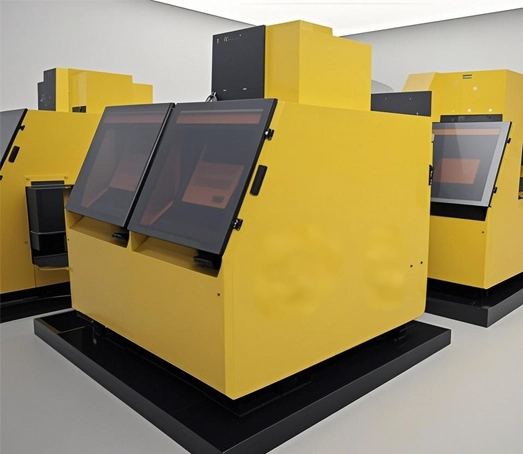

A large-capacity copper recycling machine is designed for high-volume processing. It efficiently separates copper from various sources like thick cables. With advanced technology, it has high-speed operations, ensuring rapid and accurate copper recovery, ideal for industrial-scale recycling.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский