Advantages of Magnetic Separator

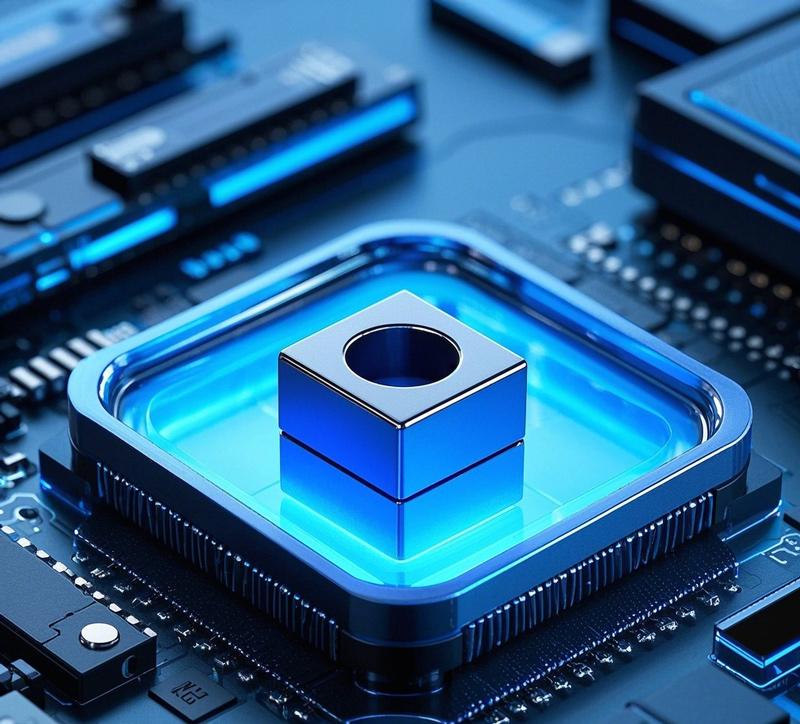

1. Advantages of magnet materials using magnetic separation equipment

High magnetic materials (such as Ndfeb permanent magnet, ferrite) :

Strong magnetic field strength: NdFeb permanent magnets can produce extremely high magnetic fields (up to 1.5 tesla or more), effectively adsorb small magnetic particles.

High temperature resistance: Ferrite and aluminum-nickel-cobalt materials maintain stable properties in high temperature environments.

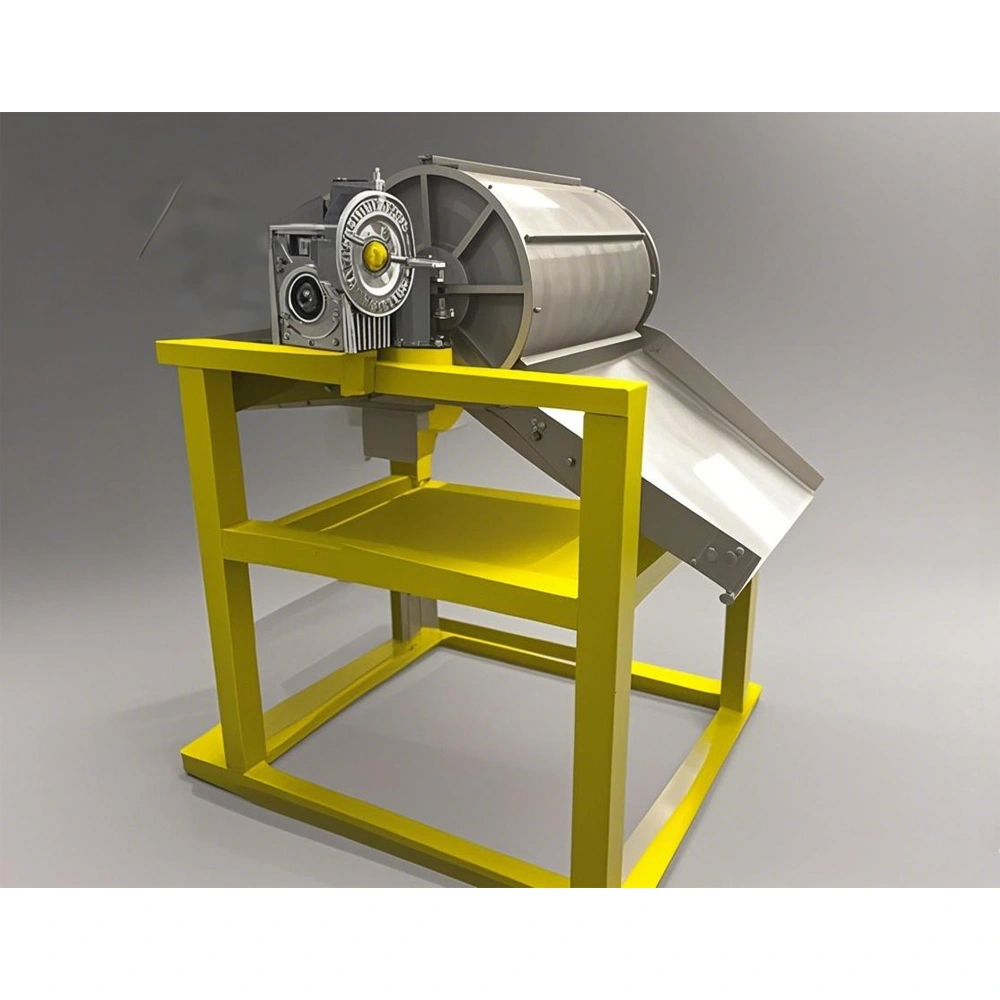

2. Advantages of shell and drum material using magnetic separation equipment

Stainless steel or wear-resistant alloy steel:

Corrosion resistance: suitable for humid or corrosive environment (such as chemical industry, wastewater treatment).

Wear resistance: Extended equipment life when handling materials containing sharp particles (such as ore).

Rubber or polyurethane coating:

Buffer protection: reduce the impact of materials on the drum wear, reduce noise.

3. Advantages of internal structural materials using magnetic separation equipment

Lightweight design: reduce equipment energy consumption and operating costs.

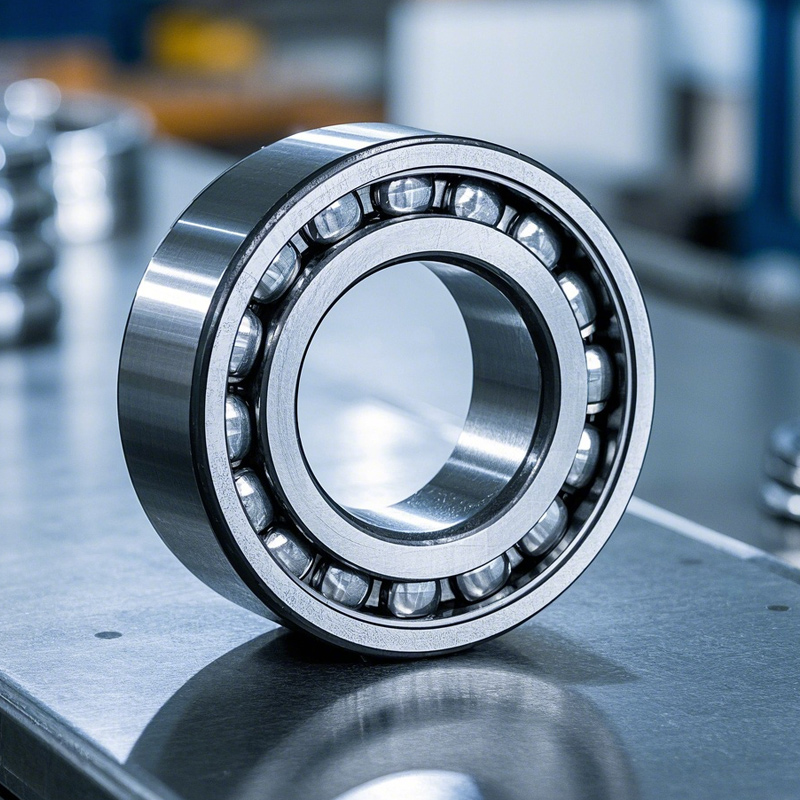

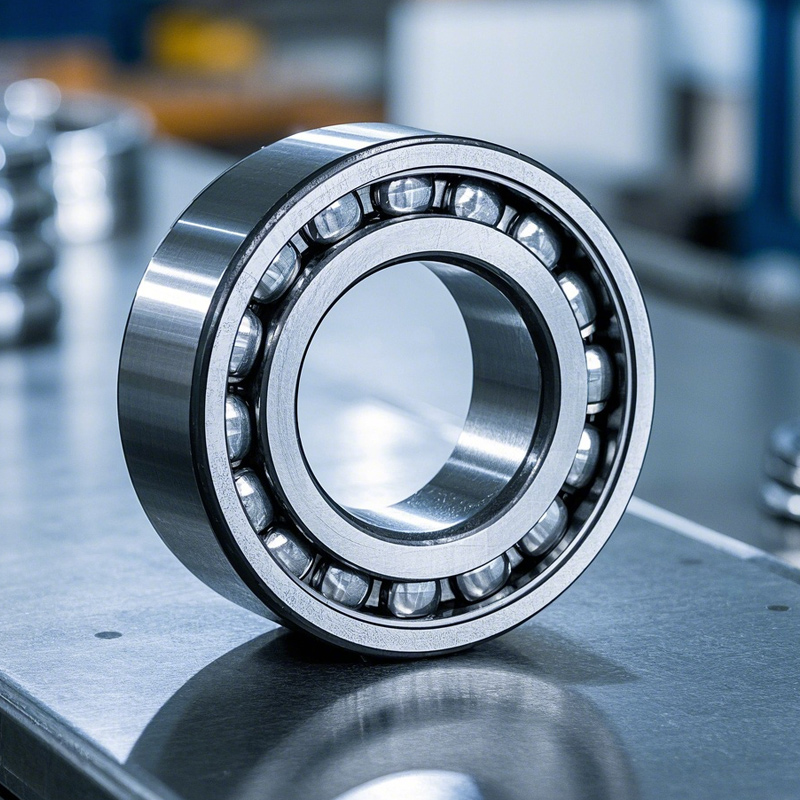

4. Advantages of bearing and sealing materials using magnetic separation equipment

Stainless steel bearing:

Corrosion resistance: Adapt to wet or dust environment, reduce maintenance frequency.

Fluoro rubber seals:

High temperature resistance and chemical stability: suitable for harsh working conditions

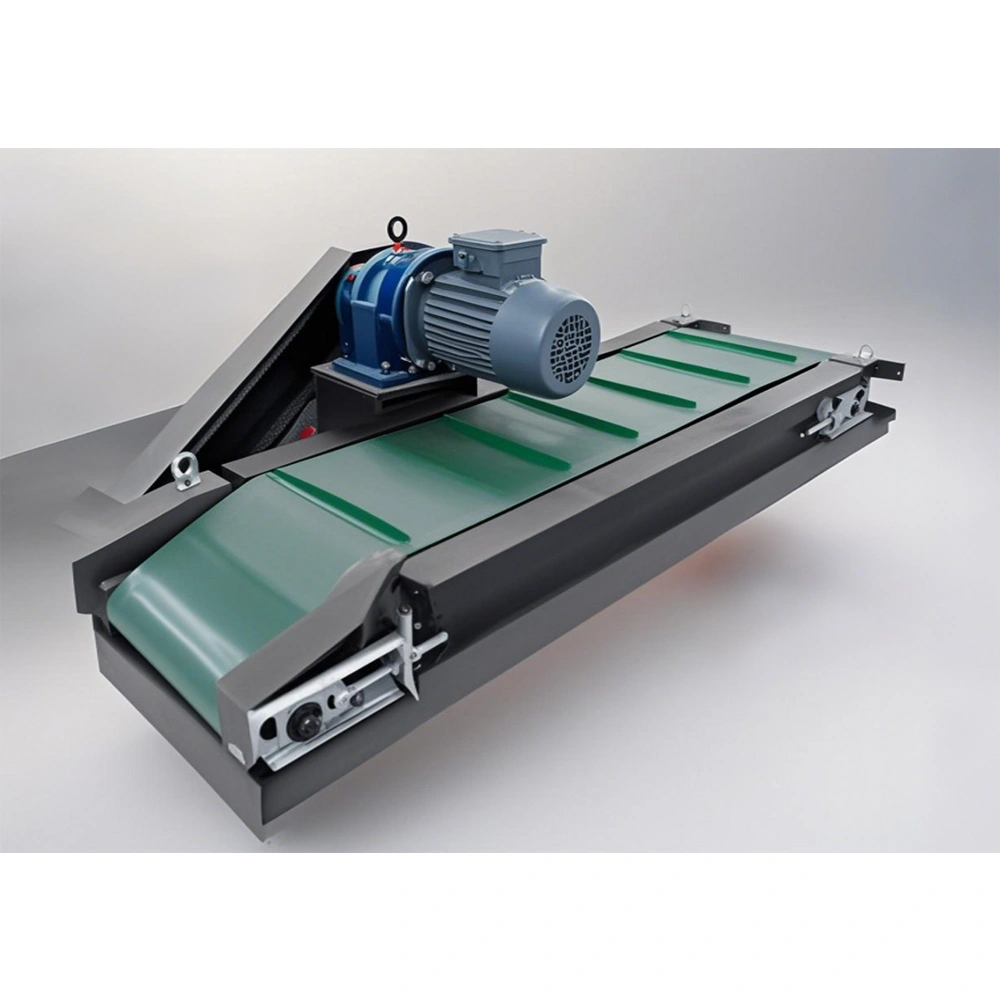

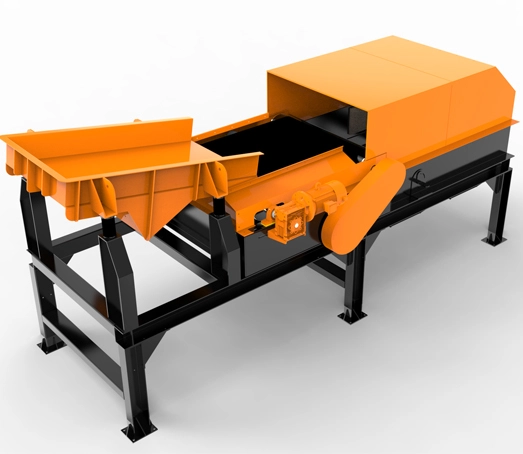

Applications of Magnetic Separator

Magnetic separator in the metal recycling industry is mainly used for the efficient separation and recovery of magnetic metals from scrap metal, industrial waste and electronic waste, while assisting the separation of non-magnetic metals. The following are the application scenarios and corresponding device types:

1. scrap metal sorting

2. electronic waste (E-Waste) treatment

3. industrial waste and tailings treatment

4. special metal recycling

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский