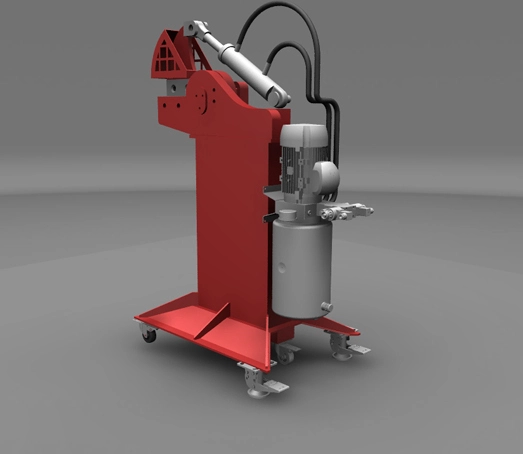

Metal shears offer numerous advantages in scrap processing. They provide precise cuts, ensuring clean and accurate pieces for easier handling and recycling. Their high - speed operation boosts productivity, reducing processing time.

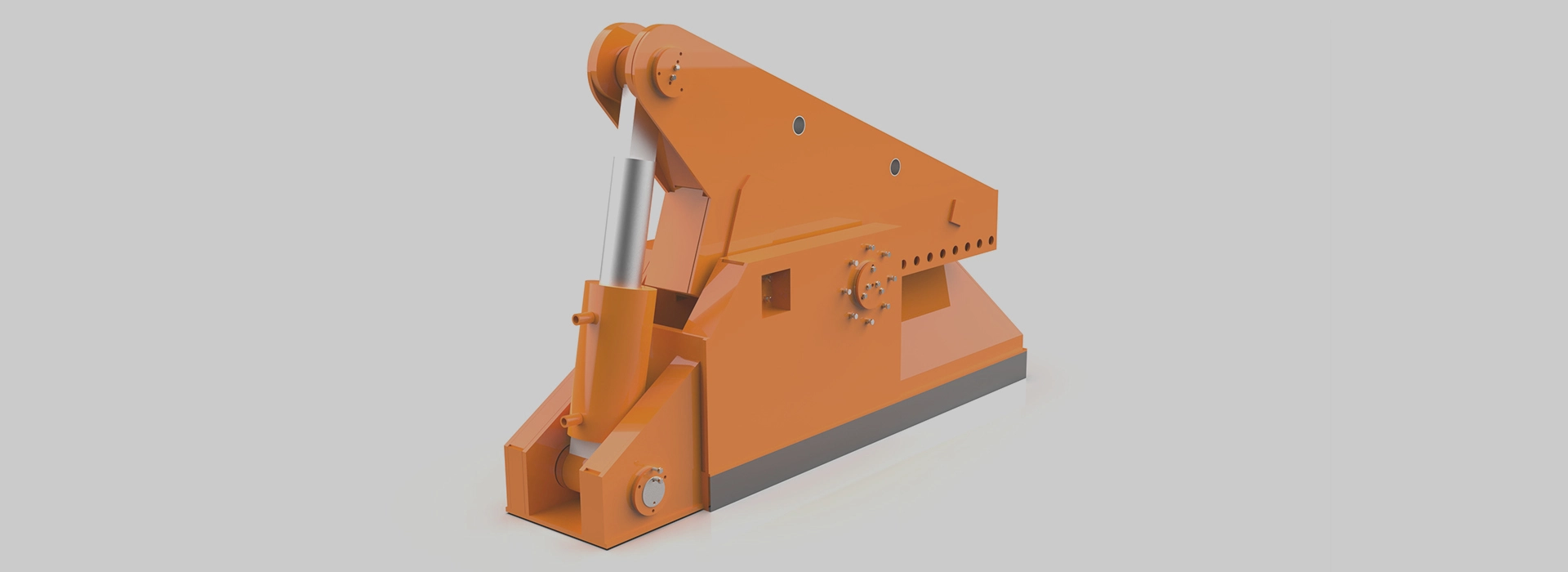

A metal shear is a crucial industrial tool. It cuts various metals like steel, aluminum, and copper with precision. Equipped with sharp blades and a powerful mechanism, it can handle different thicknesses, enabling efficient metal processing for manufacturing, recycling, and fabrication.

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский