Advantages of Trommel Screen

1. The screen is often made of 304 stainless steel or carbon steel, which has the following advantages:

Corrosion resistance: suitable for handling chemical substances or wet materials

Easy to clean: smooth surface, reduce material adhesion, avoid clogging

Long life: strong wear resistance, extended equipment maintenance cycle

Punching plate:

Punch plate: high durability, suitable for handling heavier materials

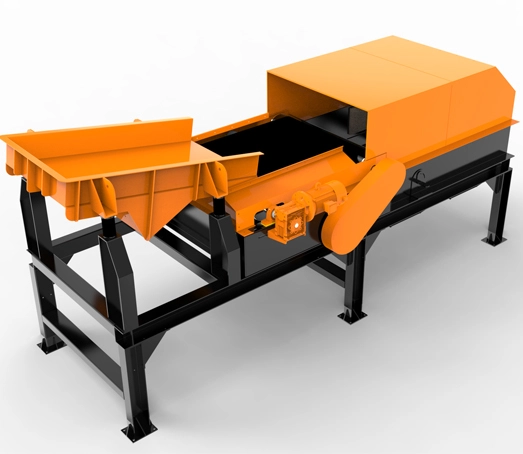

2. Strengthening design of cylinder structure

Steel roller:

The cylinder is usually made of steel, and the surface can be welded with spiral blades to enhance the material propulsion capacity, while ensuring the overall structural strength to meet the needs of large processing volumes.

Sealing and environmental protection materials:

Some devices use sealed isolation covers to reduce dust leakage, meet environmental requirements, and are suitable for environmentally sensitive scenarios.

3. Maintenance and cost effectiveness

Modular design:

The screen can be quickly replaced to reduce downtime, especially for scenarios where screening accuracy needs to be adjusted frequently.

Low energy consumption materials:

The lightweight design of the cylinder and screen reduces drive energy consumption and meets energy saving requirements.

Applications of Trommel Screen

1, the application of classification in metal recycling

The roller screen separates the metal waste of different particle sizes through the screen aperture to achieve efficient separation and purification, which is suitable for

E-waste disposal,

Metal and non-metal separation, scrap steel/scrap aluminum recycling,

Car dismantling scrap, precious metal recycling, tailings reprocessing

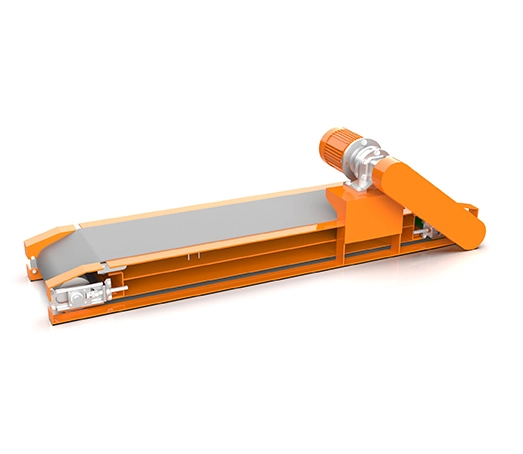

2. polishing applications in metal recycling

The roller screen treats the metal surface through friction or grinding media to enhance the recovery value, mainly used in

Metal surface cleaning and impurity removal, improve surface finish

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский