Advantages of Turbo Mill for Sale

1. Efficient removal of grinding heat

Airstream takes the heat generated by grinding from the product.

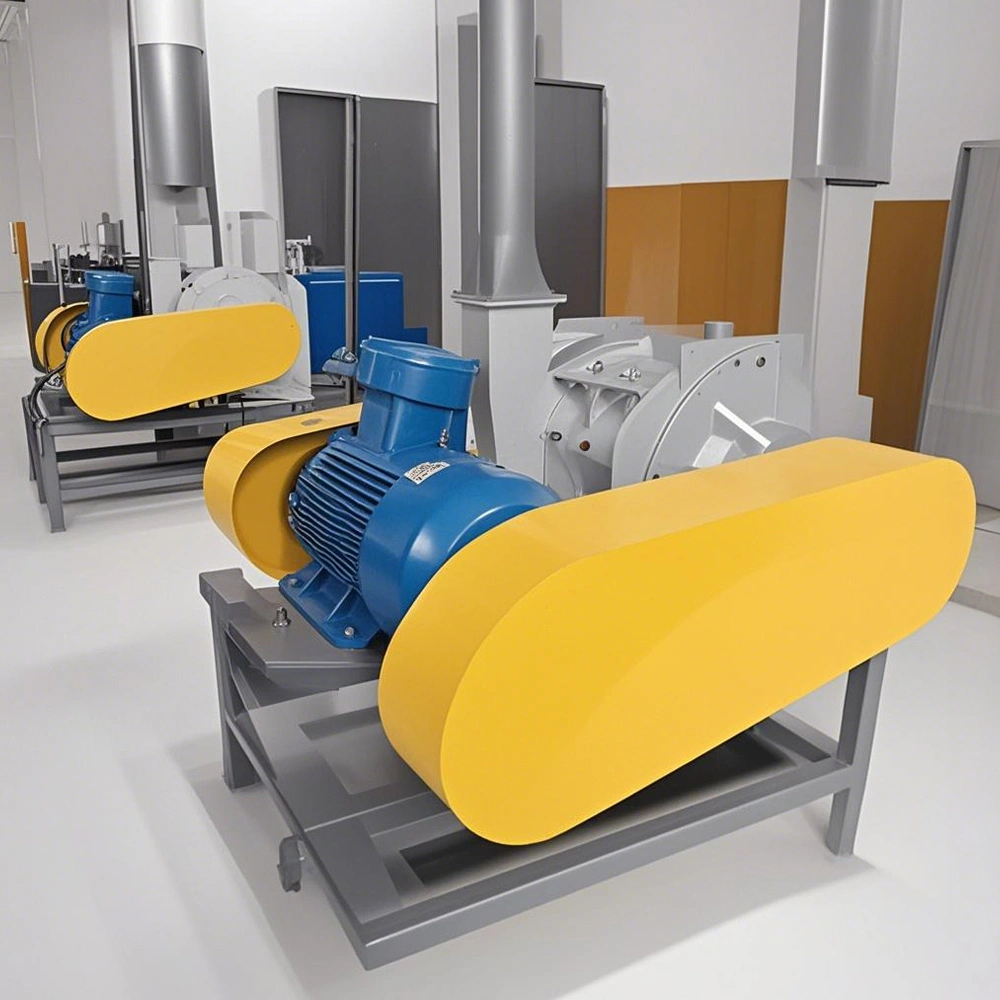

2. Robust machine construction

As it has no screen inside and the structure is very simple that makes long time running possible without trouble.

3. Low costs peripheral equipment

Since Turbo Mill itself generates airstream, required system air volume is relatively small and the investment costs on peripheral equipment like suction blower is accordingly low.

3. Crushing temperature rise is low, especially for thermoplastic and fibrous materials, product size uniformity;

Horizontal design, maintenance, operation and cleaning convenience.

4. Dust-free operation.

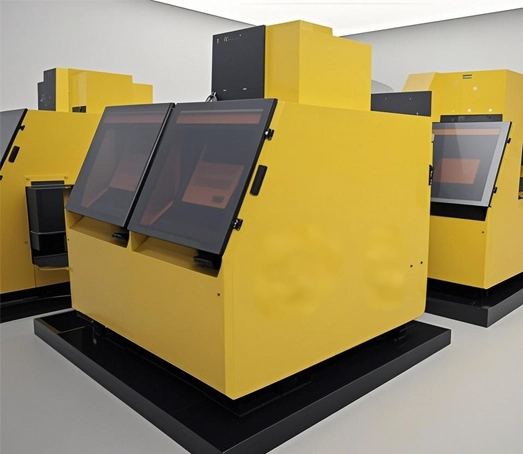

Applications of Turbo Mill for Sale

TURBO MILL's application in the field of copper-plastic separation focuses on the efficient recovery of metal resources in waste cables, and its core functions are reflected in the following aspects:

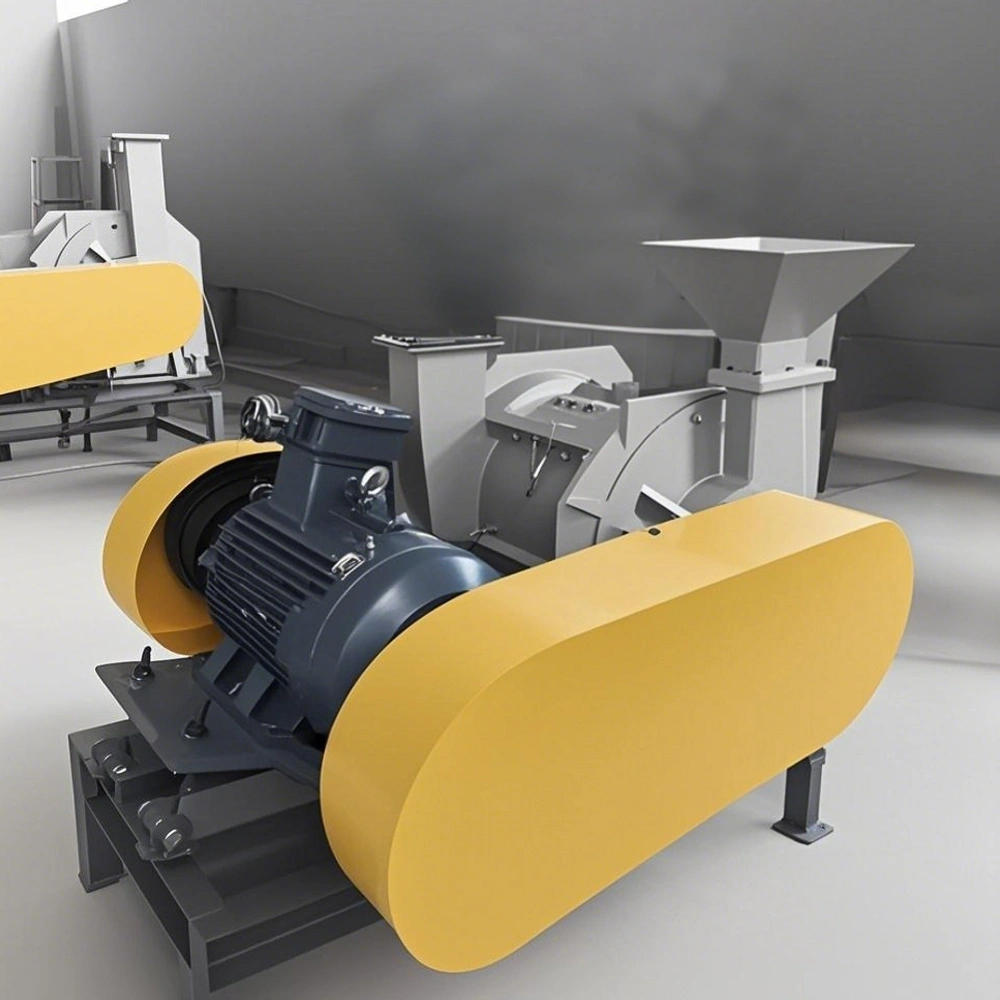

Mixed material breakage: Through the combination of high-speed rotating tool and wear-resistant liner, communication cables, power lines, automotive wiring harnesses and other waste cables of different specifications can be broken, destroying the physical combination of copper core and plastic insulation layer.

Intelligent screening separation: The screening system equipped with the equipment uses the density difference between copper and plastic to achieve granular separation through vibration or airflow, the copper recovery rate can reach more than 99.9%, the purity of plastic is more than 95%, the separated copper particles can directly enter the smelting process, and the plastic debris is used for recycling granulation.

Complex scenario adaptation: For cables containing aluminum, steel tape armor and other complex structures, to ensure the complete separation of multi-layer cladding structure, especially for the treatment of fluorine plastics, rubber and other difficult to separate materials.

Environmental protection and economy: The equipment is equipped with pulse dust removal device, dust emission is less than 10mg/m³, at the same time, the dual-axis synchronous drive technology reduces energy consumption by 30%, and the processing capacity is 5-8 tons/hour, which significantly improves the economic benefits of recycling enterprises.

The turbo milling machine has been widely used in electronic waste recycling centers, metal recycling enterprises and automobile dismantling industries, and has realized the industrialization of waste cable recycling treatment.

before

after

English

English 日本語

日本語 한국어

한국어 français

français tiếng việt

tiếng việt Indonesia

Indonesia Español

Español العربية

العربية русский

русский